26.06.2019 | LÜTZE AirSTREAM sliding nut

Flexible equipment assembly on the wiring frame

LÜTZE, the automation specialist based in Weinstadt, has expanded its sliding nuts range to include the new, load-bearing, pivotable sliding nut for the individual and flexible mounting of components on the AirSTREAM rail modules.

By using sliding nuts, rail modules can be flexibly modified or built on at any time. The sliding nuts are used in the sliding nut channel of the AirSTREAM rail modules. The components which cannot be directly snapped onto the hat profile are screwed into the sliding nut channels. With the aid of a sliding nut cage, the sliding nuts are inserted into the channel and fixed in their respective positions, thus preventing the sliding nuts from slipping out of position. They can also be used vertically. If two sliding nuts are placed in the respective position, the components or the adapter rail can be directly fitted to the module and individually placed.

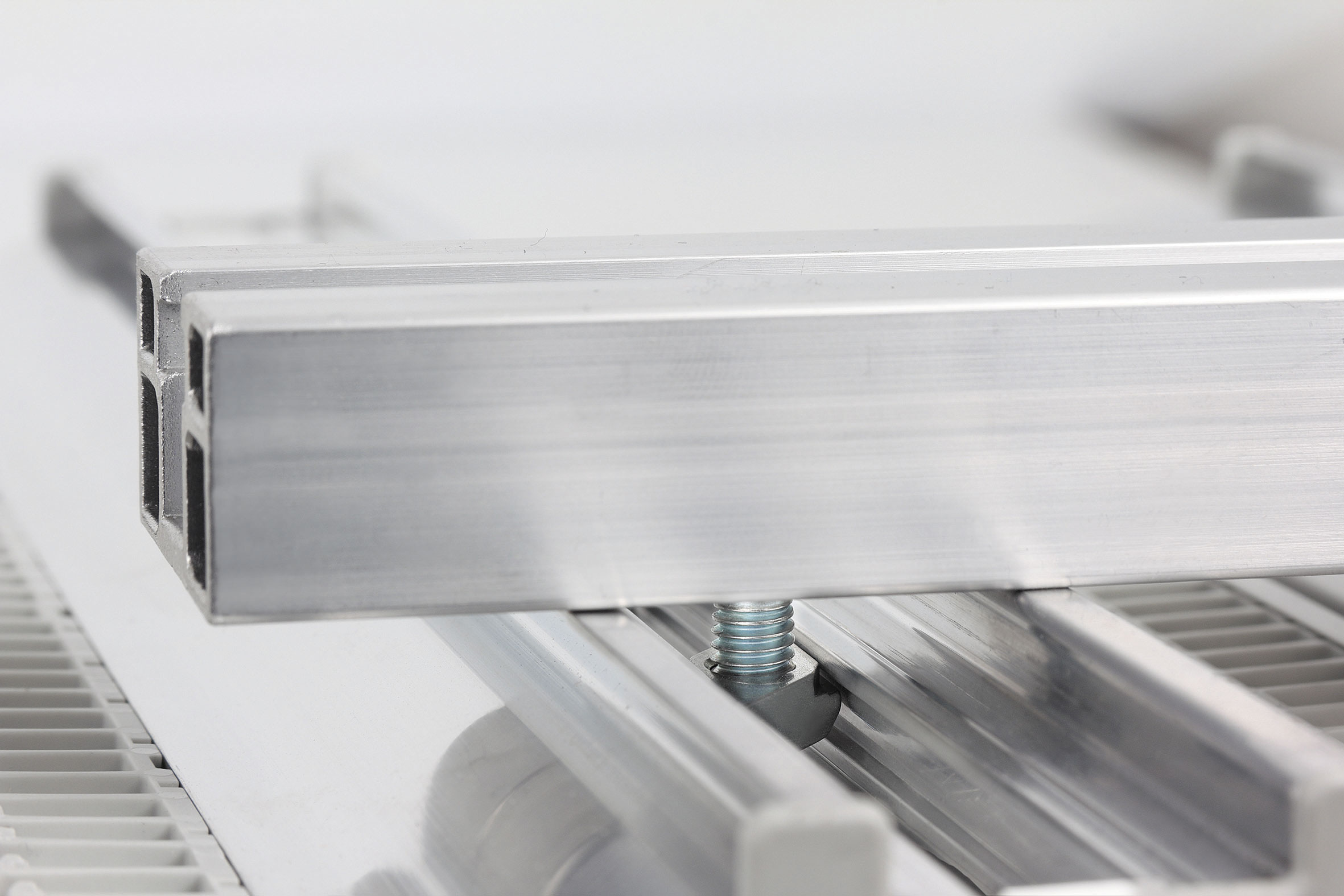

Fig. 1.: Trapezoidal pivotable sliding nut

The trapezoidal, pivotable sliding nut measures 13 x 10 x 5 mm (W x H x D) and can be inserted into the profile in any given position without an additional cage. This is of benefit when components or adapter rails need to be retrofitted, and the wiring rack to the left and right is already occupied. This negates the need to insert the sliding nuts into the channel from the side or to mechanically adapt them.

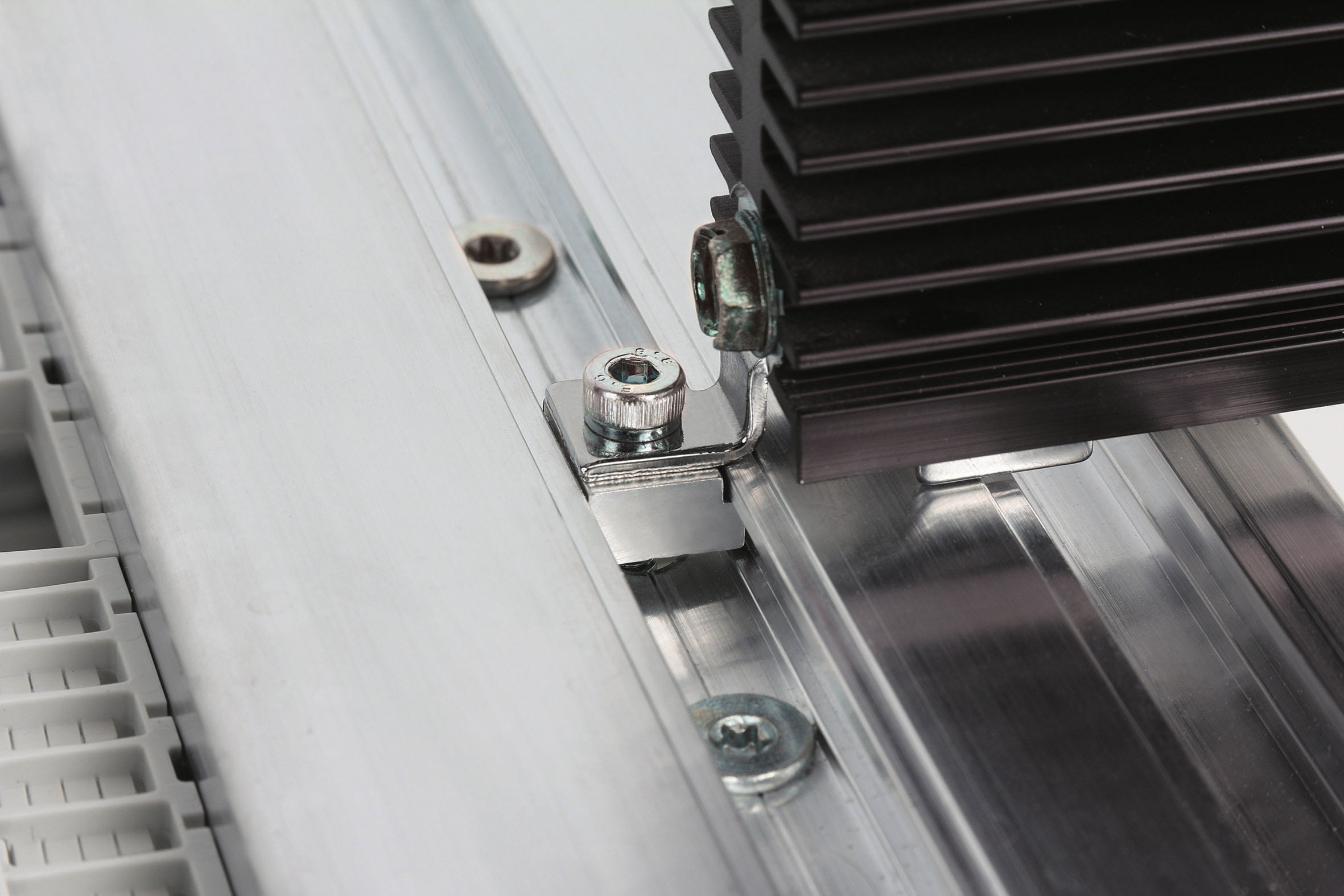

The GLS special sliding T-nut provides a flat surface for mounting rails (MS/MA) and adapter rails (RG 035). For components which are screwed directly to the AirSTREAM wiring rack, this prevents the mounting plate from deforming or the plastic base from breaking.

The load-bearing sliding nut is 25 mm long, 13 mm wide and 4 mm deep. With its wide contact surface, it is ideally suited for the mounting of heavy components.

Fig. 2.: Flexible equipment assembly with the hat rail sliding nut on the AirSTREAM frame

All sliding nuts are made of zinc-plated steel. They are available ex works in PU of 10 pieces.

Fig. 3.: LÜTZE product manager Michael Bautz presents practical accessories for the energy efficient and space-saving AirSTREAM wiring system

About AirSTREAM

LÜTZE's AirSTREAM wiring system provides a compatible range for all standard control cabinet systems.. Its main advantage is the improved heat distribution inside the control cabinet. This prevents hotspots and provides a homogeneous climate in the control cabinet, while also allowing energy savings of up to 23% to be made in cooling the cabinet. With the principle of intelligent air guidance, LÜTZE is one of the technical pioneers of control cabinet air conditioning. The LÜTZE AirSTREAM wiring frame combined with the AirBLADES provides targeted guidance of the air flow within the control cabinet, and also for optimized air circulation inside the cabinet. The LÜTZE AirBlower balances out the air layers in the control cabinet and achieves optimum heat dissipation. LÜTZE engineers have come up with highly efficient instruments, software tools and intelligent accessories for designing control cabinets and thermal simulations. For instance, the AirTEMP thermal analysis tool can be used from the outset to detect as a result of the wiring method, thermal problems and overheating components, equipment distribution and arrangement, and cooling type.

Characters incl. spaces: 3.271