07.11.2024

Proactively prevent machine downtime through condition monitoring in control cabinets

Optimize production processes with condition monitoring: intelligent temperature monitoring for control cabinets in systems and production lines with AirTEMP Controller and AirTEMP Monitor.

Automation specialist LÜTZE, Weinstadt, introduces a new solution for temperature monitoring and efficiency improvement in industrial production: Condition monitoring of control cabinet temperature offers operators of systems and production lines, an innovative way to monitor, optimize, and significantly increase operational efficiency.

Fig. 1: AirTEMP Controller unit for thermal monitoring of control cabinets

| Download Photo |

Aiming to centrally and efficiently monitor combinations of multiple control cabinets equipped with the AirSTREAM wiring system, this solution enables thermal monitoring through a single AirTEMP Controller unit. This central control not only improves monitoring efficiency but also minimizes installation and maintenance efforts.

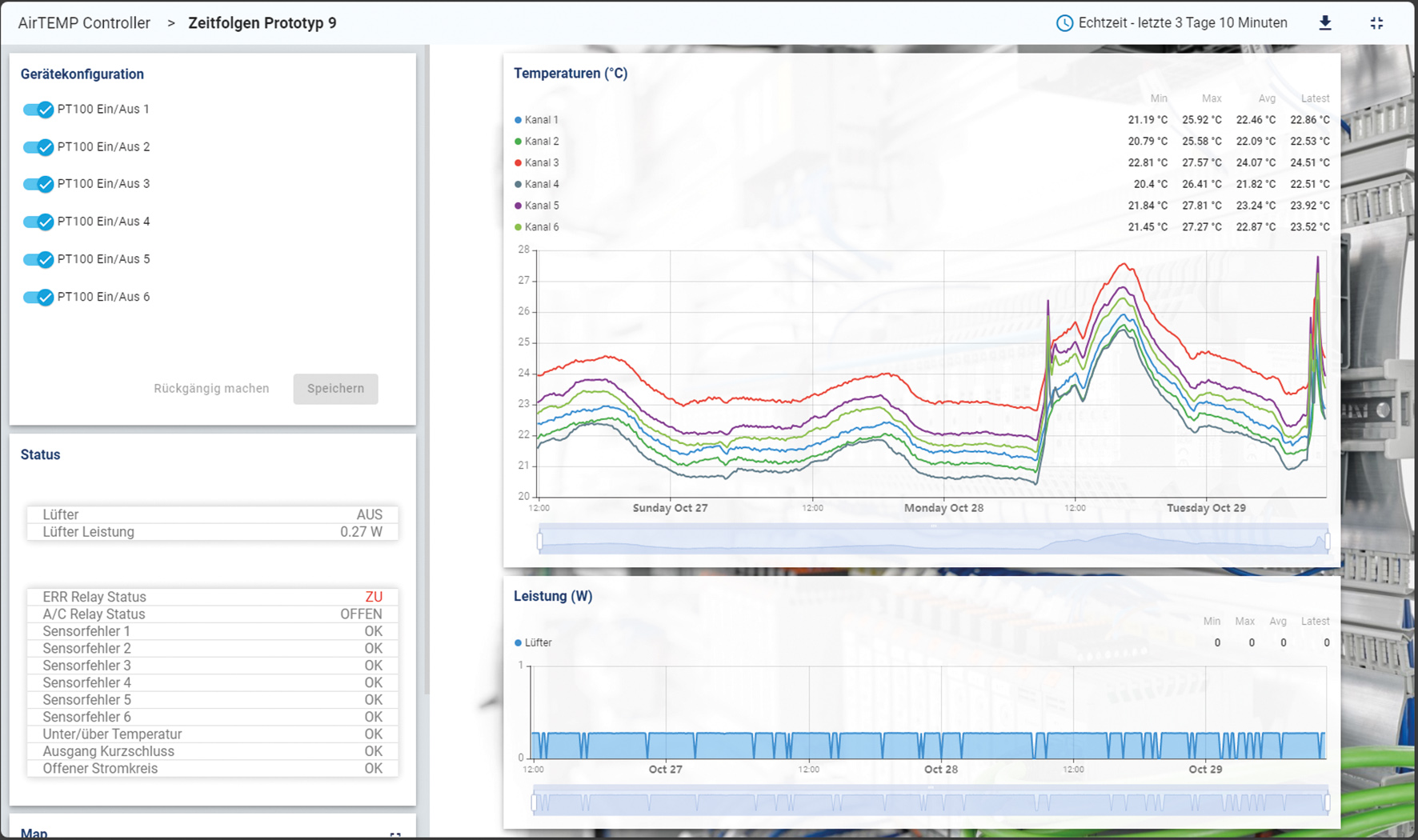

A key element of the solution is cloud-based implementation, enabling external access for operators to plants in various production sites worldwide. Users can access relevant data at any time and from any location, and adjust operating parameters as needed. The user-friendly AirTEMP Monitor dashboard, allows real-time viewing of control cabinet temperature data, ensuring quick response to potential issues.

The solution is complemented by flexible reporting features: Weekly or monthly reports and analyses can be sent via email, providing detailed information on the condition of individual control cabinets. Another crucial aspect is the intelligent alarm system, which sends immediate notifications in case of malfunctions or over-temperature, allowing operators to proactively address critical conditions and prevent downtime.

Implementing this condition monitoring in the control cabinet sustainably enhances the efficiency, safety, and reliability of production processes, and optimally secures system availability.

Additionally, the AirTEMP condition monitoring solution incorporates demand-driven cooling: Active cooling solutions can be connected to the system to efficiently influence cycle performance, enabling energy savings and reducing CO2 emissions.

Fig. 2: Setting up alerts and accessing relevant data for condition monitoring via the AirTEMP Monitor dashboard

| Download Photo |

About the AirSTREAM System

The AirSTREAM wiring system is the quasi-standard for spatially and thermally optimized control cabinets with high energy-saving potential, thanks to optimal space utilization without cable channels, smart accessories, and intelligent planning and simulation tools.

Characters with spaces: 3,027